Sengchai Transformer with 50 years experience. Their beginning was small.

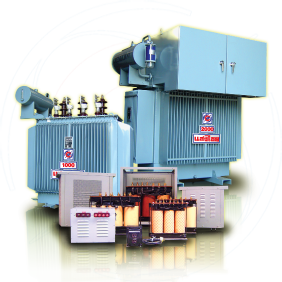

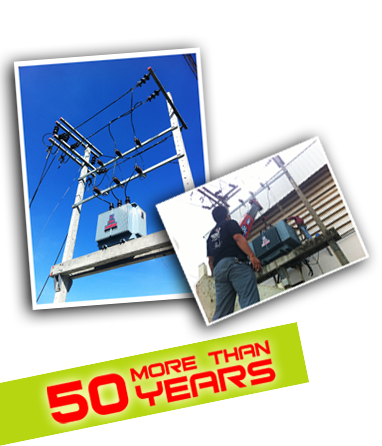

They began as a small shop to the entire country of Thailand, keeping their quality up to this day, which is acceptable for both public and private sectors. This complies with ANSI, ICE, DIN, ISO 384-2543, ISO 9001 : 2008 and ISO 14001.

The Sengchai Company Limited is a manufacturer of power transformers and distribution transformers from high to a low voltage, built to a high standard, which pioneered the first transformers in Thailand. There were only 2-3 transformer companies in Thailand then. Sengchai optical transformers have been produced since 2495.

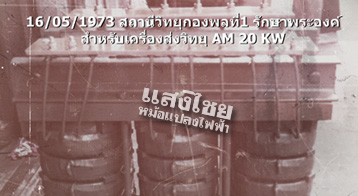

In 2506, they were fortunate to have built a good customer base. During The Vietnam War, Thailand became the base operations for the USA. In the period The Americans ordered many transformers from Sengchai. Then...